Client: Aisin Texas Corporation | Location: Cibolo, TX

Our customer had a problem with how to efficiently respond when a unit was discovered to be defective while on the assembly line. Specifically, once a unit was discovered to be defective, it could not be removed from the assembly line and inspected until after it reached the END of the assembly line. Not removing a defective unit from the assembly line sooner results in confusion as well as potentially wasted manpower and materials downstream. In addition, inspectors had to wait until the defective unit exited at the end of the assembly line to begin their work.

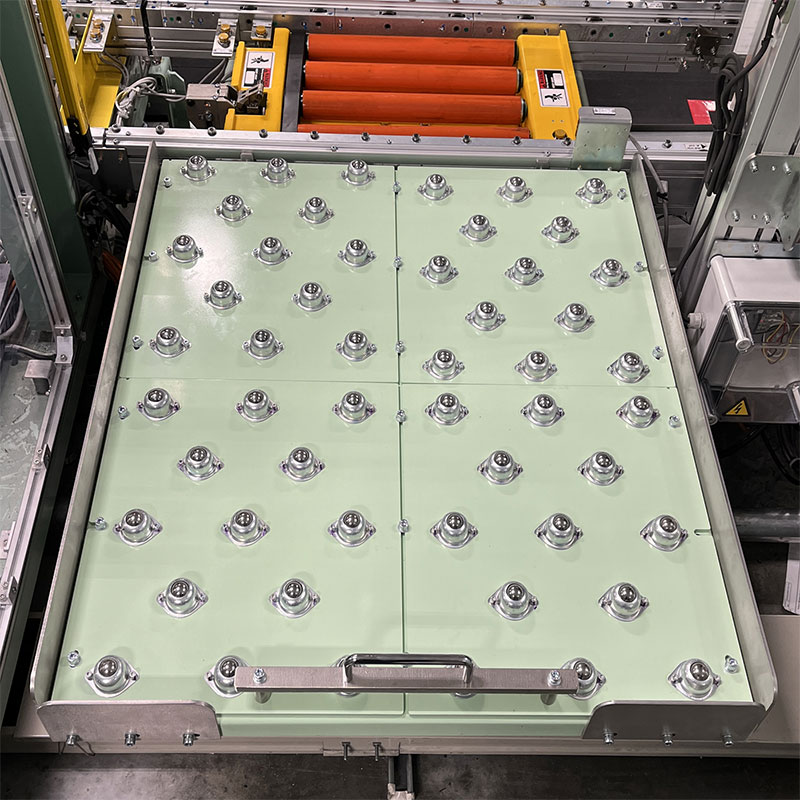

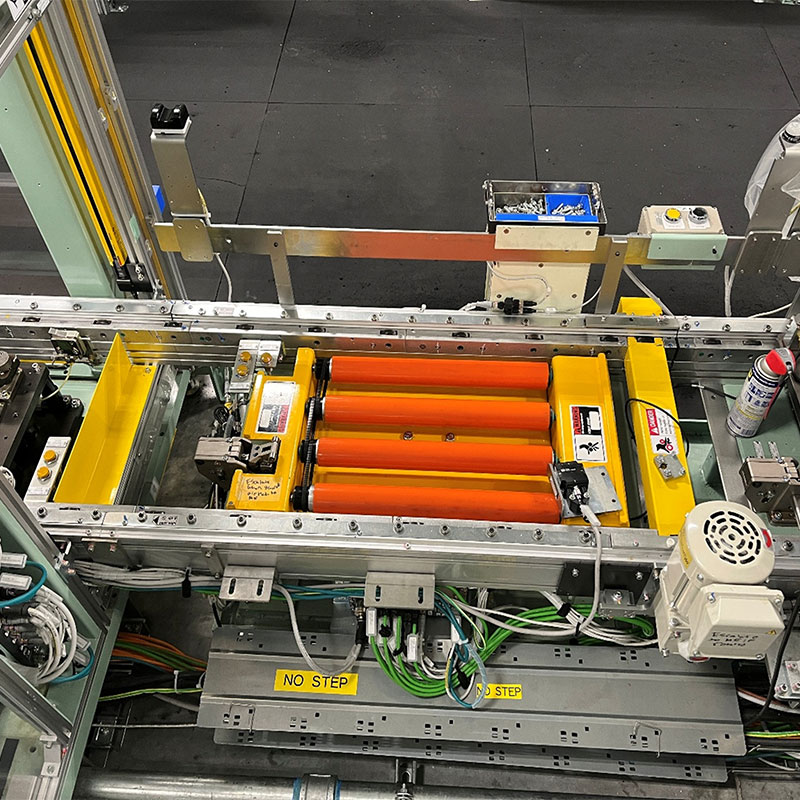

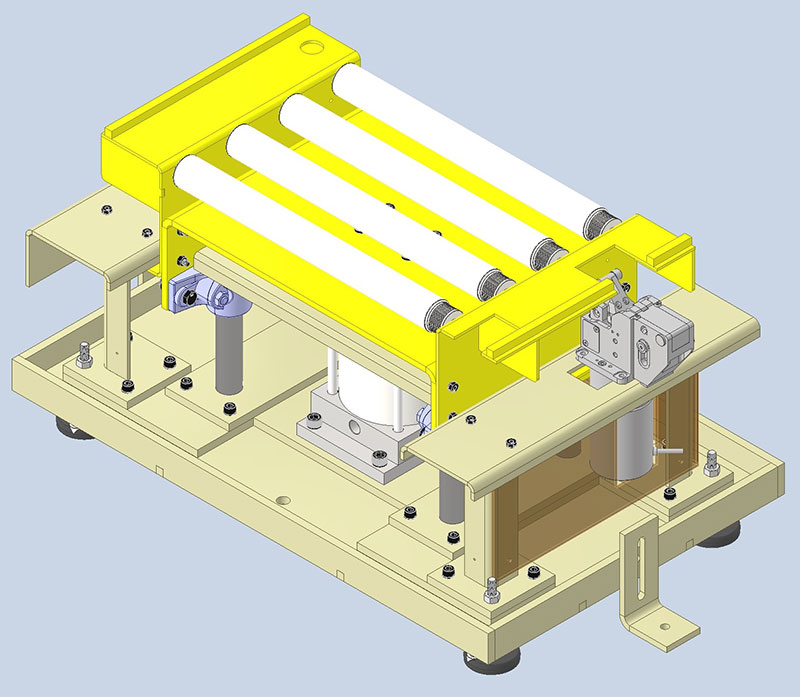

The decision was made to install a Diverter Unit and Roller Ball Table. The purpose of a Diverter Unit is to raise the assembly from the assembly line motorized rollers, and re-direct it onto a non-moving table. The Diverter Unit and Roller Ball Table would be located BEFORE the end of the assembly line so that defective units could exit the assembly line sooner. Additionally, a second Diverter Unit and Roller Ball Table would be installed so that the repaired assembly unit could re-enter and resume its path on the assembly line.

The decision was made to install a Diverter Unit and Roller Ball Table. The purpose of a Diverter Unit is to raise the assembly from the assembly line motorized rollers, and re-direct it onto a non-moving table. The Diverter Unit and Roller Ball Table would be located BEFORE the end of the assembly line so that defective units could exit the assembly line sooner. Additionally, a second Diverter Unit and Roller Ball Table would be installed so that the repaired assembly unit could re-enter and resume its path on the assembly line.

In addition to its mechanical features, the Diverter Unit needed to include sensors, actuators, and integrate with the assembly line’s existing PLC logic programing so that it interacted with units that were marked as defective, only.

SNAI was tasked with submitting a proposal to execute these changes. Our initial plan was to purchase a Diverter Unit that is manufactured by the same manufacturer of the assembly line. Doing so would ensure many specifications were met with ease. However, we learned that the manufacturer’s lead time was 22 WEEKS. This did not align with the customer’s goals, and was deemed unacceptable.

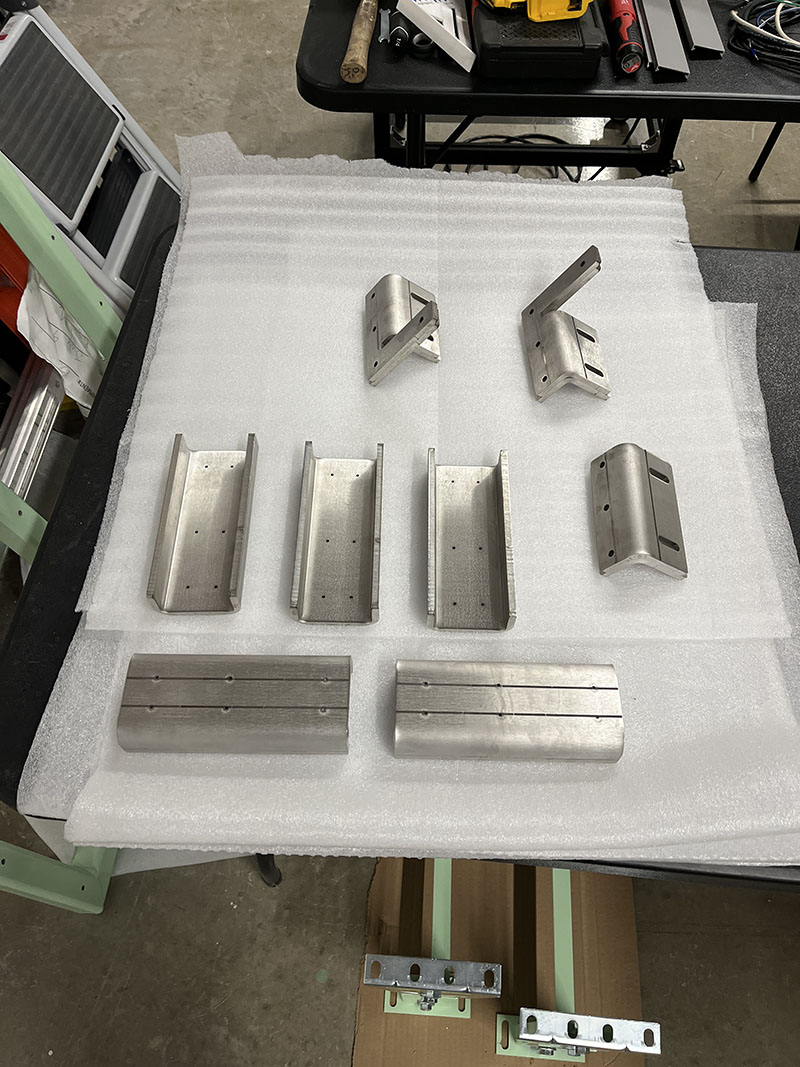

In response, our next best option would be to design, fabricate, assembly, and install (2) alternative Diverter Unit and Roller Ball Tables that were compatible with the existing assembly line specifications, including its performance cycle time and paint finish. We researched and proposed a custom solution that was competitively priced to the manufacturer option, and deliverable in 10 WEEKS.

Our proposal was accepted. Design work was completed and approved by the customer in (5) weeks, Fabrication was completed in (5) weeks, and delivery & installation was completed on schedule. Our alternative Diverter Unit and Roller Ball table allows defective units to exit the assembly line and seek attention much sooner in addition to re-entering the assembly line once repaired.