Automation

Control Services

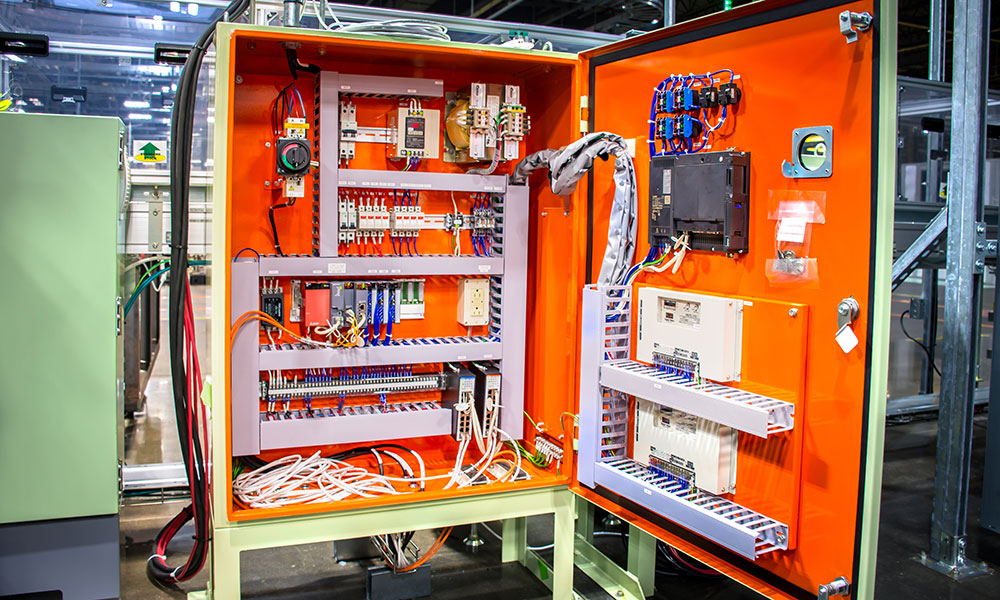

Our automation control systems empower manufacturers to optimize operations through real-time monitoring, improved communication, and enhanced quality control across every stage of production.

The SNAI Andon production control system delivers the benefits of lean manufacturing that eliminates waste and production inefficiencies and improves communication between manufacturing operators, team leaders, and external technicians. Andon provides real-time monitoring of all manufacturing stations from a centralized control center within the production line to lower manufacturing costs and correct issues that could potentially result in production downtime.

Our control systems continuously collect and display data to observe equipment status and provide employees with information to help them gain more valuable insights into potential issues that could lead to bottlenecks and equipment defects. With visual and auditory alerts, they empower employees to stop production when a quality issue is detected and make more informed decisions to optimize manufacturing processes and improve production rates.

Manufacturers gain consistent and accurate data that can be used to track trends, make the entire process more efficient, and lead to streamlined communication between employees. Our clients can continually analyze issues on the plant floor to reduce unplanned disruptions and leverage automation and strategically deployed sensors to reduce human error and achieve greater quality control.

SNAI Automation control systems include:

Parts Indicating Systems

SNAI deploys parts indicating systems that improve quality control throughout the entire manufacturing process with automated tracking solutions that reduce human error and cut production costs. It leads to greater inventory visibility, better regulatory compliance, and offers valuable insights into parts usage to identify potential cost savings.

Production Traceability Systems

SNAI provides real-time monitoring of products and components at each stage of manufacturing, providing up-to-date information as to status and location. Also known as QC data logging systems, our innovative technologies and automated data collection systems quickly identify quality issues and prevent bottlenecks and delays while also analyzing and optimizing production processes.

Assembly Production Assignment Systems

SNAI offers assembly production assignment systems that reduce the entire production process into smaller and coordinated tasks that lead to higher output, eliminate repetitive processes, and reduce idle time. Seamless coordination through assembly production assignment allows for data-driven decision making based on real-time data and wider quality control at every stage of production.

Control Devices & Sensors

SNAI deploys the finest control devices and sensors on the market today to guarantee reliable, time-saving, and safe operations in all industries. We offer the top control device brands in the world including Mitsubishi, Omron, Keyence, Idec, SMC, Patlite, and Rockwell. They make automated tasks run smoother, minimize waste, and help lower labor costs.

Project Spotlight

Conveyor Sorting System – Integration

The client requested a solution at one assembly line to store parts on a temporary basis, where it would be delivered with an AGV (Automatic Guided Vehicle). Once the availability…Read More »

Automatic Vision inspection and Programming for Part Identification

The client wanted to implement vision systems at multiple assembly lines that identified several types of parts so that the next processes are decided by the specific identified part type….Read More »