Support and Consulting

SNAI collaborates with manufacturers to identify automation opportunities and designs that are tailored strategies to optimize operation and gain advantages in the marketplace.

Real-Time Production Monitoring and Lean Manufacturing with Running Smoothly

We help companies reduce the risks of accidents and integrate safety protocols to protect personnel, equipment, and products. During the consulting phase, we recommend new and evolving technologies that reduce labor costs, integrate seamlessly into existing systems, and help plan for growth with scalable solutions.

Your End-to-End Partner in Smarter Manufacturing

We take a holistic approach to automate and streamline custom manufacturing systems to create smooth workflows optimized to dramatically reduce production cycle times without affecting quality. We also develop manufacturing strategies to save money by minimizing material waste while increasing energy efficiency to lower operational costs.

We work with clients from the planning stage all the way through construction to systems installations. Our extensive experience and knowledge allow manufacturers to adapt wisely and adopt the latest technologies to gain an edge in competitive markets.

Project Spotlight

3-Piece Prototype Tool Holder Set

We noticed an extended cycle time at one of our customer’s assembly line stations. During our research, we observed the technician spending unnecessary time carefully relocating a power tool to…Read More »

Plant Expansion – AC Power Distribution

Summary SNAI designed and installed the AC power distribution system for multiple new assembly lines at their customer’s plant expansion project. Details The scope of SNAI’s power distribution work began…Read More »

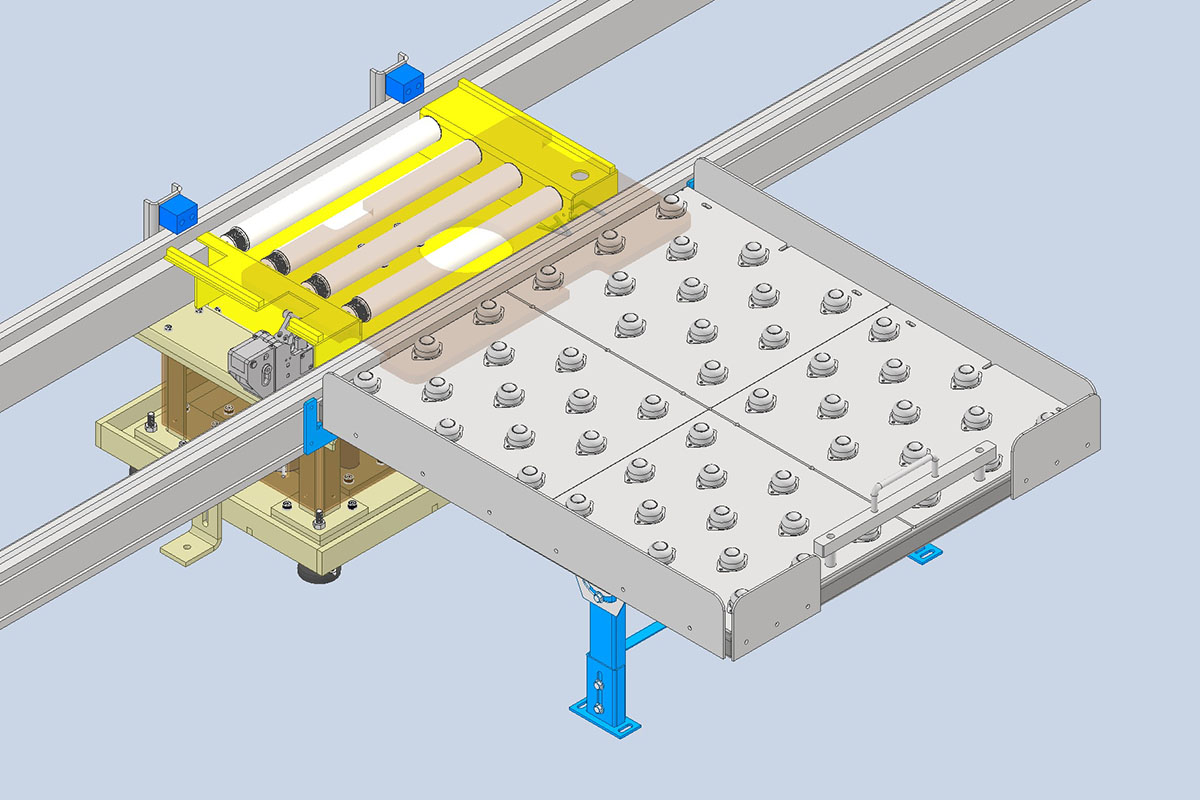

Assembly Line Kick in/out Conveyor Set

Our customer had a problem with how to efficiently respond when a unit was discovered to be defective while on the assembly line. Specifically, once a unit was discovered to…Read More »